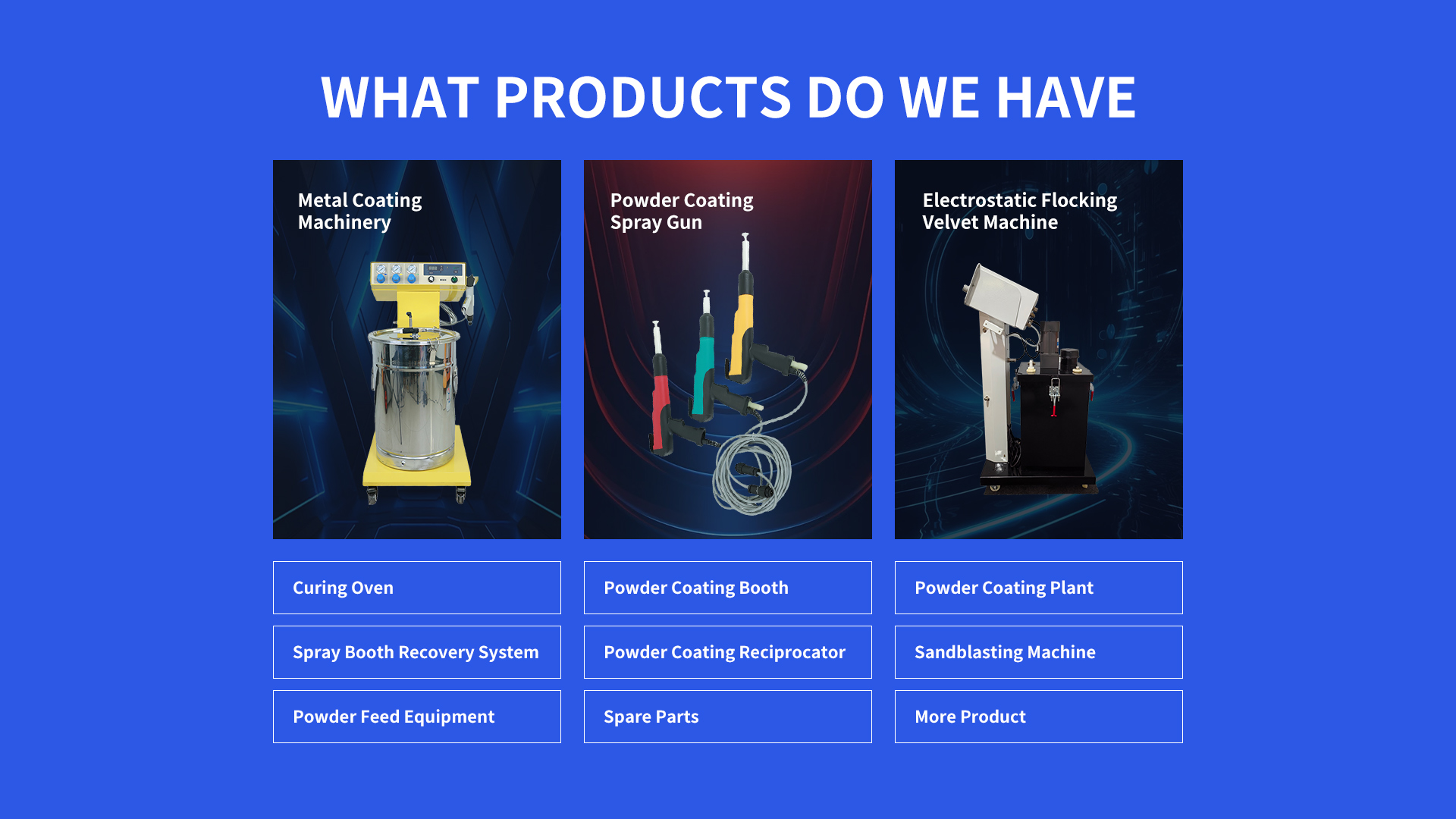

Industrial Powder Coating Machines High-Performance Solutions for Large-Scale Manufacturing

Introduction to Industrial Powder Coating Machines

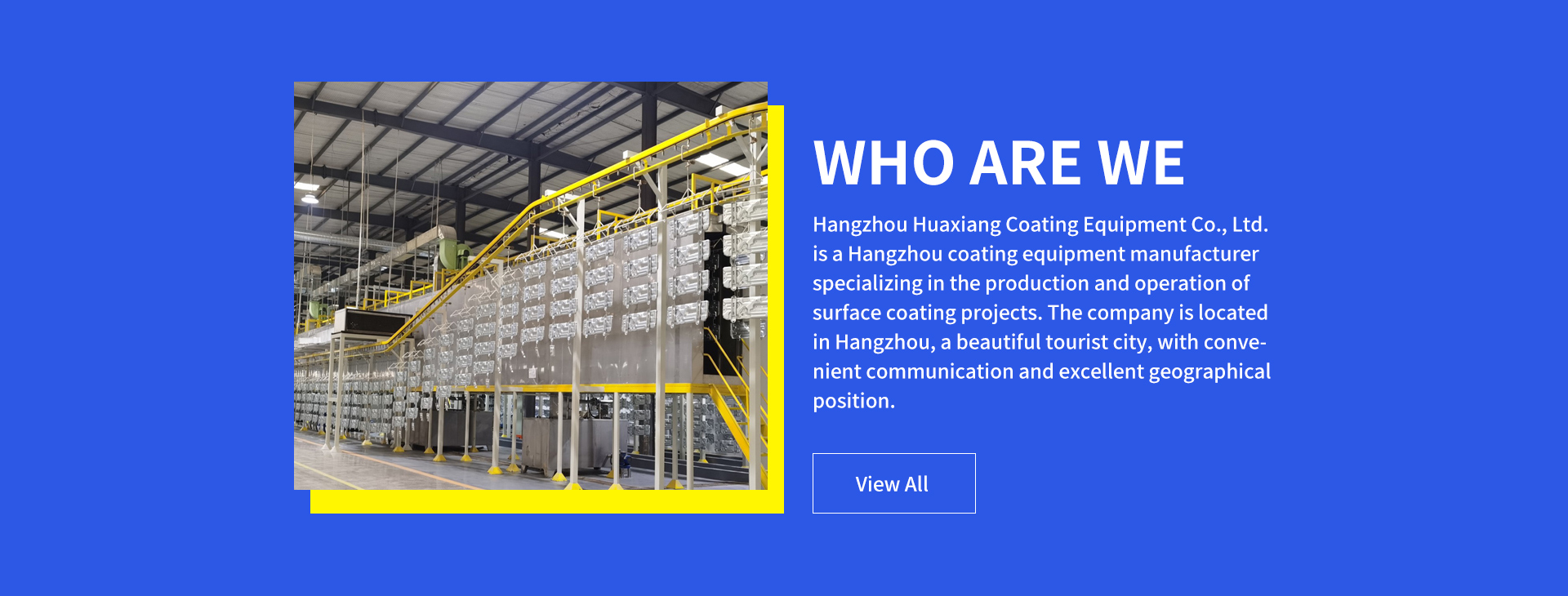

Industrial Powder Coating Machines are heavy-duty systems designed to deliver high-quality, durable finishes for metal products in large-scale manufacturing. These machines use electrostatic principles to apply dry powder evenly onto surfaces, which is then cured into a resilient layer under heat. Ideal for automotive, aerospace, and construction industries, industrial powder coating machines offer superior efficiency, reduced waste, and zero VOC emissions. With features like automated conveyor systems, advanced recovery units, and programmable controls, they streamline production while ensuring consistent results. Their robust design and scalability make them indispensable for factories prioritizing speed, sustainability, and cost-effectiveness.

Electrostatic Spray Booths: Equipped with multiple guns for uniform coverage on large or complex parts.

Powder Feed and Fluidization System: Includes bulk hoppers, pumps, and sieves to ensure continuous powder flow.

Curing Ovens: Large-scale ovens (up to 300°C) with precise temperature controls for rapid curing.

Recovery Systems: Cyclonic or cartridge-based units to recycle 95%+ of oversprayed powder.

Advanced models integrate automated conveyor belts, PLC controllers, and real-time monitoring sensors to optimize industrial powder coating machine efficiency and minimize downtime.

2. Industrial Powder Coating Machine Applications

These Industrial Powder Coating Machines are pivotal in:

Automotive Manufacturing: Coating engine blocks, chassis, and wheels for corrosion resistance.

Aerospace: Applying heat-resistant finishes to turbine blades and aircraft components.

Construction: Protecting structural steel beams, pipelines, and roofing materials.

They also serve niche sectors like appliance production (refrigerators, ovens), agricultural machinery, and medical device fabrication, where high-volume output and precision are critical.

3. Design Considerations for Industrial Powder Coating Machines

Key design factors include:

Safety: Explosion-proof booths, proper grounding, and fire suppression systems.

Energy Efficiency: Heat-recovery ovens and insulated chambers to cut power costs.

Scalability: Modular designs allowing integration with existing production lines.

Maintenance: Easy-access panels for cleaning and replacing filters. Prioritizing these elements ensures industrial powder coating machine durability and compliance with OSHA/ISO standards.

4. How to Select an Industrial Powder Coating Machine

Consider:

Production Capacity: Choose systems with 500–2,000 kg/hour throughput for heavy-duty tasks.

Material Compatibility: Verify compatibility with metals like aluminum, galvanized steel, or alloys.

Certifications: Opt for CE, UL, or ISO 9001-certified machines for reliability.

Budget: Industrial powder coating machine prices range from 50,000forbasicsetupsto500,000+ for fully automated lines. Evaluate long-term savings from energy use and powder recovery rates.

5. Industrial Powder Coating Machine Q&A

Q: Can these machines coat non-metallic materials?

A: No, electrostatic coating requires conductive surfaces. Pre-treatment or conductive primers may enable limited use on plastics.

Q: How to prevent powder clogging in guns?

A: Maintain optimal humidity levels and perform regular industrial powder coating gun maintenance.

Q: Are these systems eco-friendly?

A: Yes, zero solvent emissions and high powder reuse rates align with sustainable manufacturing practices.

Q: What safety gear is mandatory?

A: Use respirators, flame-resistant clothing, and anti-static footwear per industrial coating safety guidelines.

Q: How long is the curing cycle?

A: Typically 15–30 minutes, depending on part size and oven efficiency.

Title:Industrial Powder Coating Machines High-Performance Solutions for Large-Scale Manufacturing

Link:http://www.hpowdercoating.com/pcms/show/1216.html

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com

Keywords:

Industrial Powder Coating Machine,Powder Coating Machine